External Visual Observation![]()

All into-stocking parts undergo visual observation and inspection details will be record,

Manufacturer, Part Number, Quantity, Date Code, Rosh

Outer packaging inspection,

1.whether the packaging is complete, 2.whether packaging materials meet the corresponding MSL standard.

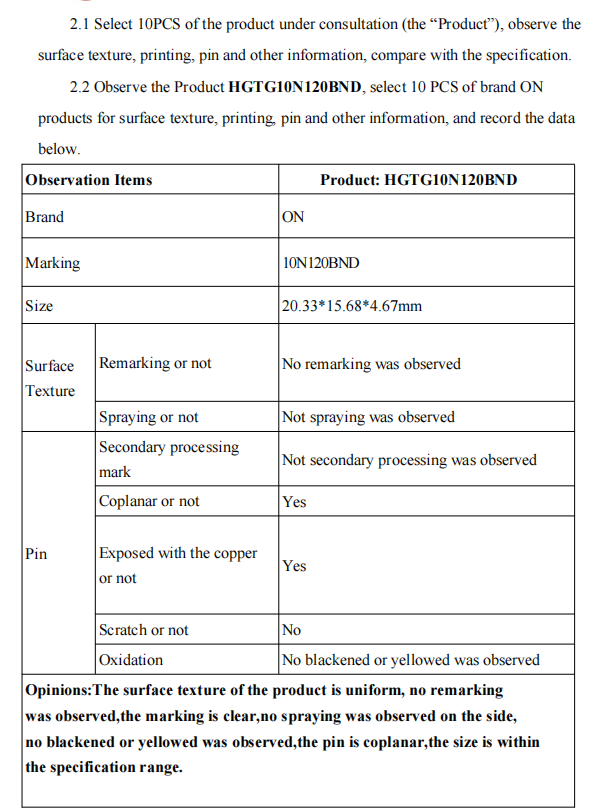

Marking Inspection, Consistency Inspection, Verification of original factory specifications and explanatory documents.

external visual observation, dust condition, deformation of Pin feet, and signs of oxidation on Pin feet.

HS code inspection, whether it is consistent with the invoice/packing list information

Engineer Recheck![]()

Non Original suspect found in external visual observation, or parts are not provided by "1st Tier Suppliers" in system,

will undergo engineer re-inspection.

1.Review external visual observation process

2.Confirm with the quality control database and check the manufacturer's label

3.Barcode scanning detection

4.Verify with the original factory the production date of Lot No. and the corresponding origin of the wafer/packaging

5.Simple electrical performance testing.

Lab Quality Testing![]()

All goods that cannot be identified during the engineer's re inspection process will enter the lab quality testing process

1.Solderability testing

2.D-CAP analysis

3.Anatomic analysis

4.Electrical performance conformance testing

5.Inspection and testing analysis report.